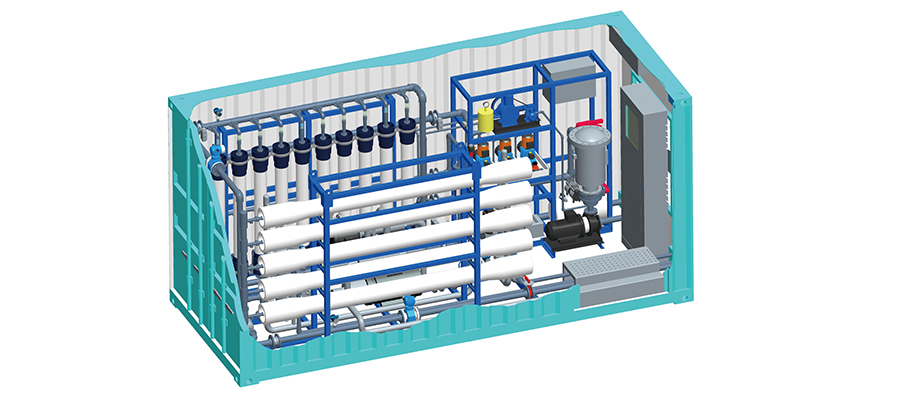

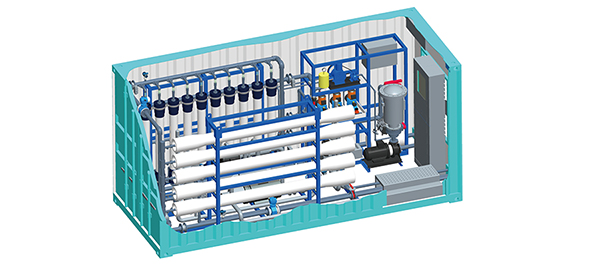

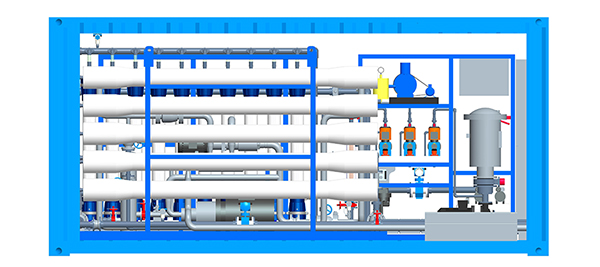

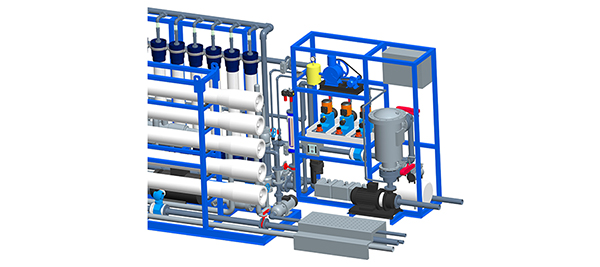

Containerized UF-RO Seawater Desalination Plant Containerized Desalination Plant with Ultra-Filtration and Reverse Osmosis System

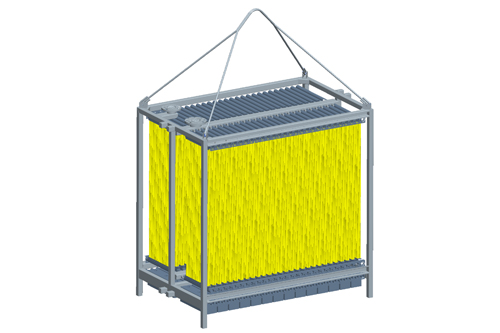

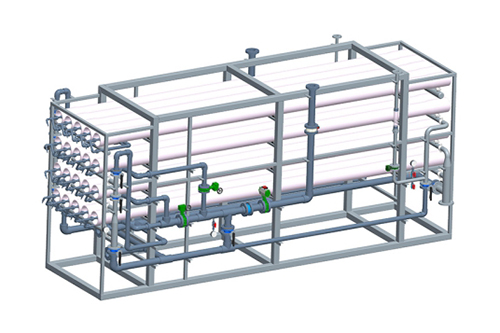

The containerized seawater desalination plant is a water treatment solution that combines ultra-filtration (UF) and reverse osmosis (RO) systems which are built inside metal shipping containers. Reverse osmosis membranes allow water molecules to pass through but reject salt ions and all kinds of contaminants, thereby separating water molecules from seawater via a pressure driven process. Combining the small footprint of containerized water treatment system with advantages of ultra-filtration and reverse osmosis processes, this integrated UF-RO seawater desalination plant features completely independent operation, which accommodates your seawater desalination applications at major flexibility.

- Applications

- Features

- Parameters

- Models

- Configurations

- Process

- Drinking water treatment for residential communities;

- Seawater and brackish water desalination;

- Producing pure water required in the manufacture of industrial integrated circuits;

- Producing pure water used for beverage and wine production;

- Producing softened water and desalted water for boiler plants;

- High water quality, low energy consumption and efficient energy recovery

This seawater desalination plant can efficiently remove turbidity, chromaticity and dissolved salt in seawater. The energy recovery system is also adopted to lead a high recovery rate of 70%, enabling significantly reduced energy consumption for water reuse in enterprises. - Decreased membrane cleaning frequency

Due to its hydrophilic and smooth surfaces with 3D network structure, the membranes are featured by strong antifouling property which results in decreased cleaning frequency. - Intelligent Operation

Based on PLC control system, this containerized seawater desalination plant can perform automatic water production and membrane cleaning, achieving unattended operation, online and remote control.

| Raw Seawater Parameters | |

| Water source | Seawater and brackish water |

| PH | 3-10 |

| Salinity | ≤40000mg/L |

| Chlorine residuals | <0.1mg/L |

| FOG content (fat, oil, and grease) | <2mg/L |

| COD | <1.5mg/L |

| Desalted Water Parameters | |

| Rate of desalination | >98.5% |

| Turbidity | <0.05NTU |

| Recovery rate | 30%-50% |

| Conductivity | <10μs/cm |

| Water quality standard | In compliance with international standards |

| Operational Parameters | |

| Filtration | Ultra-filtration (UF) + Reverse osmosis (RO) |

| Cleaning | Air flushing, chemical cleaning |

| Working temperature | 5-45°C |

| Working pressure | 3-5.8Mpa |

| Water production pressure | ≥0.15Mpa |

| Model | JT-50TSW | JT-100TSW | JT-150TSW | JT-200TSW |

| Production | 50m3 /d | 100m3 /d | 150m3 /d | 200m3 /d |

| Inlet | DN40 | DN50 | DN65 | DN80 |

| Container size | ISO 20ft(HC) | ISO 20ft(HC) | ISO 40ft(HC) | ISO 40ft(HC) |

| Power | 380V/50Hz/30KW | 380V/50Hz/40KW | 380V/50Hz/45KW | 380V/50Hz/50KW |

| Weight | 6T | 8T | 9T | 10T |

| Standard | Optional |

| Standard container 20GP/40GP | High cube container 20HQ/40HQ |

| In compliance with shipping & export requirements | |

| Standard module configurations, multi-media filtration (MMF) pretreatment + precision filtration + ultra-filtration (UF) + reverse osmosis (RO), scale inhibitor adding unit | Energy recovery system is optional for reducing energy consumption, second RO system can be added according to the concentrations of seawater for better desalination effect |

| Fully automatic PLC control system | Remote control, system maintenance & upgrade service |

| High pressure pipe material: 2205 duplex stainless steel |

UF-RO Seawater Desalination Process

The most critical factor for ultrafiltration reverse osmosis (UF-RO) seawater desalination process is the application of semi-permeable membrane, which permits water solution to permeate and leaves the salts and other dissolved solids behind to obtain fresh water.